SAFETY BY DESIGN

Creating a safe work environment is never a one-and-done but a continuous process of informed choices and improvements.

Choosing a forklift designed with safety in mind is an excellent first choice, but safety features can only do so much. However, combined with qualified personnel following protocol, and a well-organized warehouse, they become part of a larger system that protects workers, prevents downtime, and creates a safer, more productive work environment.

TRUCK AND FORKLIFT DESIGN

Safety is built into every part of a forklift or warehouse truck, from the frame to the smallest control feature. Stability starts with a low center of gravity and optimized weight distribution to prevent tipping, whether lifting loads at height or maneuvering in tight spaces.

Advanced safety systems further protect by continuously monitoring truck movements and automatically responding to potential risks. These intelligent features help maintain stability, prevent unsafe operations, and enhance overall control, creating a safer and more efficient working environment.

- System of Active Stability (SAS) continuously monitors key parameters and automatically adjusts to enhance lateral and longitudinal stability, reducing the risk of tip-overs.

- Operator Presence Sensing (OPS) system ensures that critical functions are disabled if the driver is not properly positioned, preventing unintended movement.

By integrating these smart technologies, Toyota forklifts help operators work confidently while minimizing the risk of accidents.

BEFORE AND DURING OPERATION

Pre-Op Checks

A safe work environment starts before the forklift is in motion. Pre-operation checks help prevent accidents by ensuring that only authorized personnel can operate the truck and that potential mechanical issues are caught early. Simple routines like checking brakes, steering, warning lights, and emergency stop functions help keep operations running safely and smoothly.

Regular and documented safety checks are essential for consistency. Download our safety checklist for daily, weekly, and long-term inspections, or contact your nearest distributor for more tailored safety solutions.

Skilled Operators & Smart Technology

A forklift is only as safe as the person behind the controls. While modern trucks feature advanced safety systems, an attentive and well-trained operator remains the most important factor in accident prevention. Proper load handling, controlled speed, and adherence to traffic rules all contribute to a safer, more efficient warehouse.

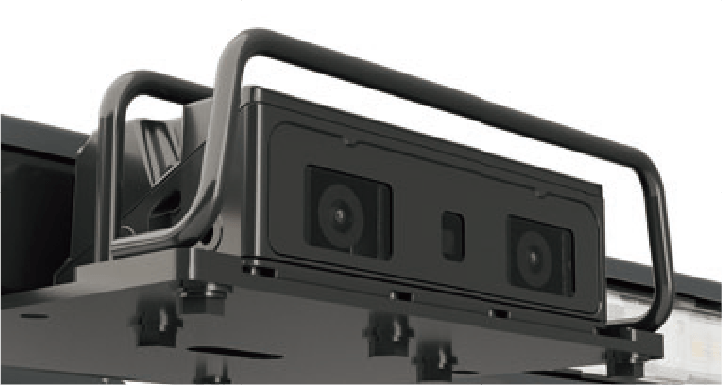

At the same time, smart technology is transforming how safety is managed. Operator-assist features enhance awareness and reduce human error, while connected systems provide real-time insights into vehicle performance and driver behavior. Learn more about Toyota’s SENS+ for collision avoidance and I_Site for fleet and operator management below, to see how technology can support a proactive safety culture.

WORKSITE SAFETY

A safe operation starts with a well-organized warehouse or worksite. Clear traffic lanes, designated pedestrian walkways, and properly marked loading zones help reduce the risk of collisions. Adequate lighting and warning signals improve visibility, while physical barriers and safety zones create a safer separation between forklifts and foot traffic. Even the most advanced forklift safety features rely on a well-planned environment to be truly effective.

SAFETY ACCESSORIES

To enhance safety in your workplace, explore a range of accessories designed to improve visibility, communication, and traffic management. Visit your local Toyota Material Handling distributor for expert advice, or browse our selection of forklift and warehouse accessories today.

SAFETY EVALUATION GUIDE

Ensuring a safe worksite for warehouse trucks and forklifts prevents accidents, protects employees, and maintains operational efficiency. A structured safety evaluation helps identify potential risks and implement necessary precautions.