STEP-BY-STEP GUIDE TO EVALUATING YOUR WORKSITE SAFETY

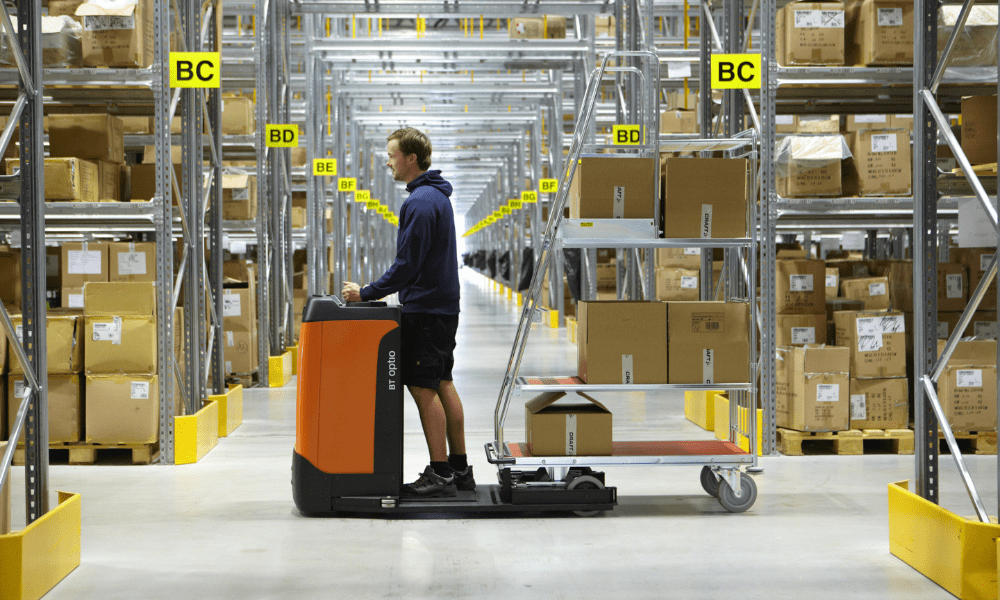

Ensuring a safe worksite for warehouse trucks and forklifts prevents accidents, protects employees, and maintains operational efficiency.

A structured safety evaluation helps identify potential risks and implement necessary precautions.

Step 1: Conduct a Risk Assessment

Start by inspecting the worksite for hazards such as obstacles, uneven surfaces, blind spots, and areas with high pedestrian traffic. Consider environmental factors like lighting, ventilation, temperature, and noise levels that could impact visibility and operator awareness.

Analyze workflows to see how warehouse trucks and forklifts interact with personnel, storage areas, and loading docks. Reviewing past incidents can also help pinpoint recurring safety issues.

Step 2: Assess Vehicle Suitability and Condition

Ensure that forklifts and warehouse trucks are appropriate for the tasks and environment, indoors or outdoors. Regular inspections should check brakes, tires, warning lights, and hydraulic systems.

Verify that operators are not exceeding load capacity limits and that safety features such as seatbelts, alarms, horns, and mirrors are fully functional.

Step 3: Evaluate Operator Training and Certification

All forklift operators should be adequately trained and certified according to local regulations. Ongoing safety training, including refresher courses and hands-on emergency drills, helps maintain compliance and awareness.

Observing operator behavior can identify unsafe practices, and fostering a safety-first mindset ensures workers remain vigilant about their own safety and that of others.

Step 4: Assess Traffic Management and Worksite Layout

Clearly marked traffic routes for forklifts and pedestrians, along with safety barriers and signage, reduce collision risks.

Speed controls should be implemented and enforced, particularly in congested areas. Aisles should be wide enough to allow safe maneuvering without unnecessary obstacles.

Step 5: Review Emergency Preparedness

A clear emergency response plan ensures workers know how to react to accidents, spills, and equipment failures. Fire extinguishers, first aid kits, and eyewash stations should be easily accessible.

Regular emergency drills help reinforce preparedness, while reliable communication systems ensure immediate reporting of incidents.

Step 6: Monitor and Improve Safety Measures Continuously

Encourage employees to provide feedback on potential hazards and areas for improvement. Conduct regular safety audits to ensure compliance and update policies based on new risks and evolving work conditions.

Technology such as telematics, cameras, and automated alerts can further enhance safety monitoring and incident prevention.