POWER SOURCES

The power sources of forklifts and trucks can be divided into two general categories: engine-powered and electric-powered. All truck types have electric models while only counterbalance forklifts and towing tractors are available with engine power.

There are also so-called hybrid systems (that combine the advantages of engine and electric) and Fuel cell technologies.

What is engine power?

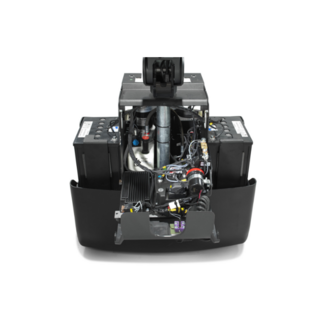

The power is generated through internal combustion (IC for short), where fuel ignites when being mixed with hot compressed air. The power is then distributed to all functions such as drive, hydraulics, and steering.

Engine power is a common power source for Counterbalance trucks and is also used for a few types of Towing tractors.

- Pros: Efficient at high speeds and rotation.

- Cons: The combustion of fuel results in emissions, making it a less suitable power source for indoor applications.

The precise design of the engine varies depending on which fuel is used and the most common fuel types are:

- gasoline

- diesel

- LPG (liquefied petroleum gas)

- CNG (compressed natural gas)

What is electric power?

Electric trucks are powered by motors and an onboard battery. The energy is stored within the battery then converted by the motors to perform different functions. Most electric trucks have separate motors for each function, such as drive, lift, etc. There are different technologies available for both electric motors and batteries.

Motors: Today, the most commonly used motor for trucks and forklifts is AC (alternating current). Its predecessor DC (direct current), was used in forklifts but is now uncommon.

- Pros: Electric motors can deliver maximum torque at start-up, making them very efficient in low-speed operations.

- Cons: Demands planning around recharging.

Batteries: The two most common battery technologies are Lead-acid and Lithium-ion. Lithium-ion is more recent and efficient, but it's not the best choice for all operations.