AUTOMATION

Whether you are a logistics provider or working in production, the automation of specific processes can add a new dimension to productivity.

This can be done by automating processes of everyday load handling; or a complete system conversion for large operations.

BENEFITS WITH AUTOMATION

Optimize your flow of goods

Automation contributes to a consistent workflow with efficient driving behavior.

Intelligent order and fleet software minimizes transport distance and avoids clustering, improving your operation's round-the-clock productivity.

Increase the safety

Automated trucks are equipped with state-of-the-art safety laser scanners which detect any obstacle and stop when needed.

This secures a safe working environment, even when working close to humans.

Minimize damage

The highly accurate navigation and detection systems of automated warehouse forklifts will avoid causing damage to your goods, infrastructure, and trucks, which will also decrease your damage and service cost.

OPTIMIZE YOUR USE OF STAFF

By having automated trucks doing the repetitive work, your workers become available to handle more complex tasks with added value.

INCREASE YOUR ENERGY EFFICIENCY

The Autopilots can be equipped with Lithium-ion batteries that are up to 30% more energy-efficient while reducing CO2 emissions.

These trucks can be charged automatically with Lithium-ion batteries, which do not require maintenance or human involvement.

UTILIZE SMART CHARGING

With the ability of automatic charging, the trucks can charge quickly in between tasks without needing personnel or charging rooms, making it fully automated.

The charging can be done when the Autopilots are idle, have a low battery, or according to a customer-made schedule to fit the specific needs.

DISCOVER OUR AUTOMATIC TRUCKS

AUTOPILOT CDI120 - FORKLESS PALLET TRANSPORT

Toyota offers an automated forkless pallet carrier, perfect for repetitive point-to-point or replenishment applications. The Autopilot CDI120 is compact and maneuverable and comes with dedicated stations.

BT REFLEX AUTOPILOT - REACH NEW HEIGHTS

Enjoy the latest Reach truck technologies from Toyota - now available as autopilot. Introducing BT Reflex Autopilot in capacities of 1.6t and 2.5t.

ALL AUTOMATED TRUCKS

We offer a range of automated trucks to optimize efficiency and flexibility in your warehouse.

Explore the best option for you today!

Fully Automated Solutions

Together with our partner Vanderlande, we offer a wide range of integrated, fully automated solutions. With innovative systems, intelligent software, and life-cycle services, we implement fast, reliable, and efficient automation technology in your operations.

- Logistic process automation

- For warehouses and distribution centers of all businesses

- In cooperation with Vanderlande

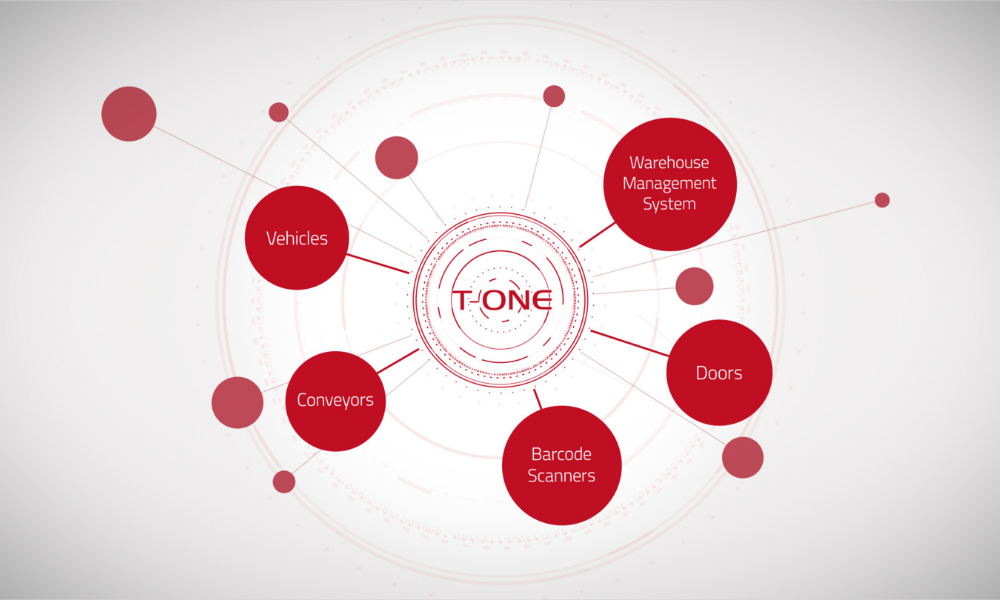

T-ONE

T-ONE is installed as an integration layer communicating with the Toyota Autopilot Automated Guided vehicles (AGVs) and your existing infrastructures, such as warehouse management systems, goods identification, and other material handling equipment.

The intelligent software offers operational robustness and optimizes warehouse resource utilization. T-ONE offers you flexibility, smooth integration, and a continuous flow of your operations.

- Intelligent automation software

- Optimize – Navigate – Execute

- In-house developed